How the Lean Six Sigma Methodology Can Be Used for L&D

Reading Time:

Lead the pack with the latest in strategic L&D every month— straight to your inbox.

SubscribeDid you know? Applying Lean Six Sigma to L&D helps to reduce process defects and better orient all training solutions around business outcomes.

Just as we suggested with total quality management, the continuous improvement methodology of Six Sigma can be focused on L&D processes.

After all, L&D should be seeking innovation and efficiency in the name of strategic business impact. In this blog, we’ll discuss how Lean Six Sigma can be applied to L&D processes, solidifying you as high-performing business function.

What is Six Sigma?

The Six Sigma methodology is designed to reduce process variation through enhanced process controls and workflow optimisation.

Lean Six Sigma goes one step further to eradicate processes and activities that don’t add value, with the ultimate aim of improving the quality of business outputs and reducing cycle times.

What is DMAIC?

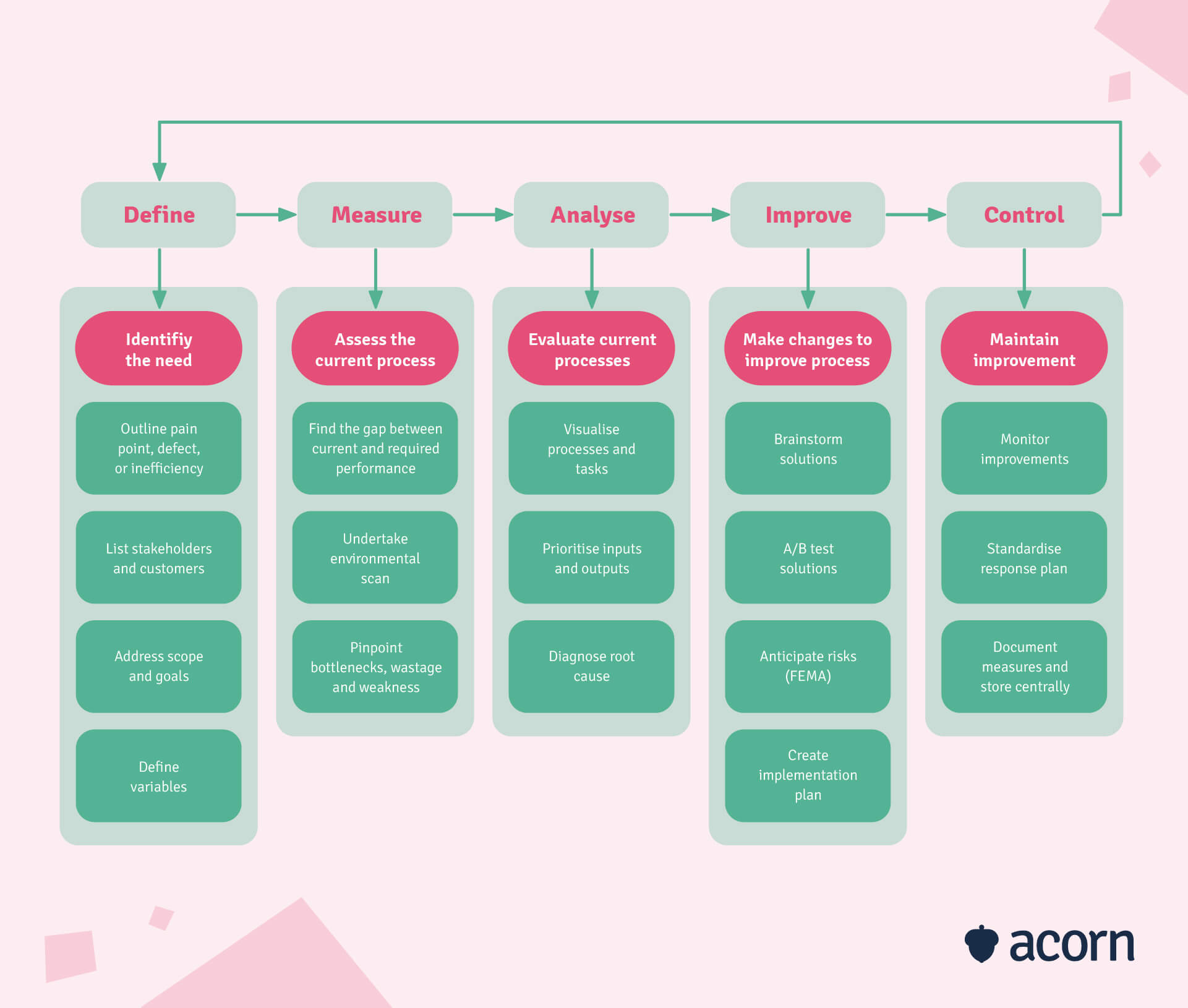

DMAIC (or define, measure, analyse, improve and control) is a Six Sigma continuous improvement processes, but it is largely applied to existing business processes.

While DMAIC is not commonly used in L&D, continuous improvement should be high on the agenda for L&D professionals.

How can Six Sigma be used for L&D?

You’re constantly verifying and validating as part of Six Sigma implementation, giving you the means with which to sustain successful gains. Which, as we know, can be the hard part of L&D, while simultaneously being the element that defines the credibility of L&D within an organisation.

After all, L&D is a process-led and standards-driven business function. Injecting a more structured basis for L&D only helps better position your team as true business partners.

Having the right technology is crucial to supporting all this. That’s part of the reason we pioneered the performance learning management system (PLMS). Built on a foundation of capabilities, Acorn PLMS enables you to build truly contextual learning experiences aligned with the performance needs of your organisation. That gives you tangible evidence of behaviour change, and therefore impact on performance.

But first, you need to translate the five phases of DMAIC into your organisational L&D processes.

1. Define

Lean Six Sigma, in its purest form, asks you to measure and optimise your processes. That starts with defining a process or activity that needs improving.

The main factors to consider and identify here are:

- Apparent inefficiencies or defects in a way of work

- Potential to reduce variables

- Assessable conditions, i.e. outcomes can be universally outlined and quantified

- Stakeholders (both project owners and those externally who are still impacted)

- Business opportunity or value creation.

Most Six Sigma explainers out there will also ask you to create a flowchart of the process value stream. The idea is that by mapping every step of the process, you’ll uncover areas of wastage and be better informed when implementing process improvement measures.

Say multiple development plans are returning basically net zero results. That means understanding the process of creating and delivering those plans: Training needs analyses, specification of learning outcomes, capability mapping, design of learning content, teaching methods, and methods of evaluation. Also, who is involved in the process and responsible for these tasks? What are the business outcomes?

2. Measure

Read the room, mark the temperature, assess the current climate. Basically: Benchmark current process performance. You need this to validate outcomes on the other side (and therefore show the impact of Six Sigma).

You’re looking for bottlenecks, inefficiencies and general areas of weakness. Look to collect specific data like:

- Environmental analyses

- Training effectiveness

- Learner engagement

- Knowledge retention.

Consider integrated systems and shared data, such as HRIS, too. Stopgaps, silos and segmented channels of communication may be more prevalent than you realise.

3. Analyse

Now’s the time to analyse the data you’ve collected on your processes.

Process mapping can help with visualising workflows in order to identify issues, as it lays out what may otherwise be tacit knowledge. The aim is to see:

- What can be simplified

- Current vs potential states

- L&D processes compared to those outside the function.

Visualisation is also particularly helpful for uncovering the root cause of waste—particularly if your team have different ideas of what needs to be improved, how things are done and what processes need improvement first.

Make sure to list all the inputs (e.g. information) and outputs (expected results) associated with a task. If the overall process is learning needs analysis, that may be an input of mapping capabilities to job roles with the expected output of a capability heatmap to feed the next task, which would be employee capability assessments.

4. Improve

Essentially, what are your solutions to the gaps left by useless tasks and to fix the underperforming ones?

This is where you want to think strategic. If this is your first time doing this, you can experiment here (within reason). Keep an end goal in mind (business outcomes, internal L&D reputation) when you decide to optimise, maximise or cut loose ends.

If you found that learning design is the problem when it comes to poor learning experiences, think again about the different inputs into that task. Technology, learning content and accessibility all might need a refresh, giving you various points through which to weed out wastage.

5. Control

All Six Sigma projects will require you to sustain changes made in the Improve phase. Lean Six Sigma methodologies further ensure your eyes stay on future prizes rather than past gains. Basically: This is the stage at which you want to make sure your solutions are sustainable and BAU.

Document the process from measurements to ROI, in order to create a standardised affair going forward. Traditional Six Sigma training uses “tollgates” in this phase, which can look like:

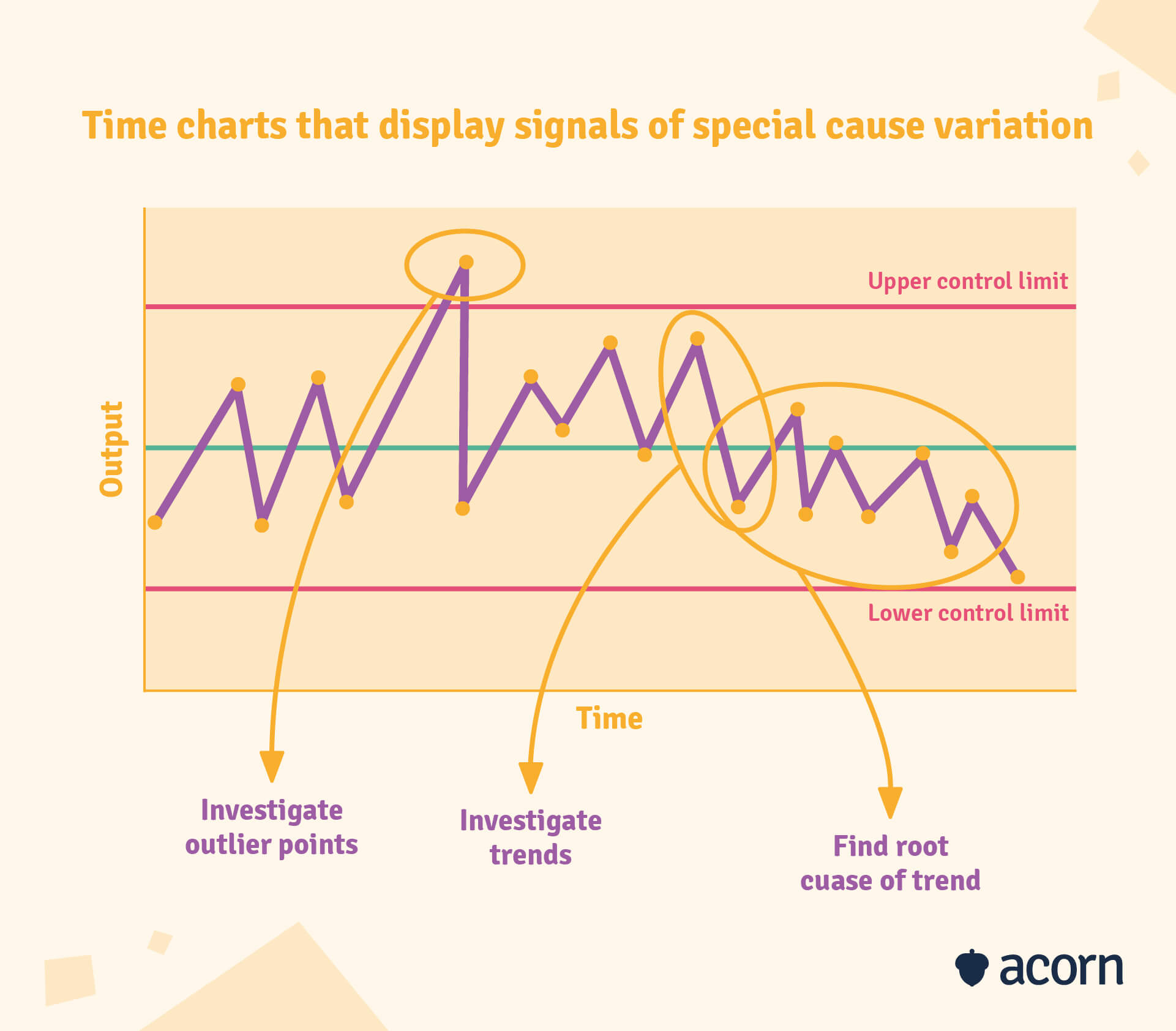

- Monitor. Compile a list of outputs (aka results) and how they are measured (think KPIs and the specific tools or processes used). Add upper and lower trigger warnings to understand high performing outliers and downturns.

- Response. In the instance more leaks are found in future, you need to have a response plan in place. What does that look like, based on the improvement solutions you’ve trialled?

- Control. Ongoing measurement and standardised responses form part of a directive overseen by a project owner or owners who ensure the continual part of continuous improvement, as well as seeking best practices.

What is the impact of L&D using Six Sigma?

Truthfully, you can take whatever process improvement and standardisation approach you like in L&D. It’s more a question of what happens if you don’t seek to improve efficiency, reduce redundancies and exploit value add.

Still, change often brings about resistance—perhaps even within your L&D team. If you give into the status quo, you’re likely just back at square one for your function with an additional legacy of failed change.

Let’s run through some arguments against introducing Lean Six Sigma tools into the L&D toolbox.

- Argument: We’re just cutting corners.

- Reframe: Six Sigma processes work smarter, not harder.

You could be over-engineering something very simple. Say you spend $1000 on a course and deck it out with all the gamification trimmings you like for an expected 100% benefits (key word: expected). Instead, you could spend $700 on the course, get almost all the same whiz-bang trimmings, receive 90% of the benefit and have $300 to spend elsewhere.

- Argument: The quality of learning will degrade without learning as the focus for L&D.

- Reframe: The focus is on business and learner value add.

If you don’t know what you’re training for and why, any program will be dead on arrival. Similarly, if you don’t know what’s a training priority and what’s not, programs may be irrelevant and come at the wrong time, therefore screwing learner engagement.

Without focusing on training effectiveness, you’ll lack a clear picture of L&D effectiveness as a whole. Which means you’re probably unaware of business alignment, too, and you won’t be able to show the value of how your budget is used. Let’s not forget that innovation and efficiency are literally industry recognised L&D capabilities, too.

- Argument: It’s too rigid to be adaptable to business needs.

- Reframe: L&D is thinking long-term and measuring what impacts the business.

Agility can’t be affected without structures to support it. The right capabilities in the right roles at the right time underpins this, as does the right capacity, which ultimately comes back to how aligned L&D is with business strategy.

Forecasting may be a value add process introduced through Lean Six Sigma. Maybe you’ll fine-tune spending or consolidate HRIS and L&D tech. Whatever the improvements, they are done in the name of fortifying L&D performance to drive business strategy.

Key takeaways

Formalising and institutionalising process improvement isn’t always the easiest task, as much as it should be part and parcel of the L&D function. Thinking outside the realm of regular L&D procedures may just be the answer. Six Sigma is traditionally focused on general business processes, but if L&D’s meant to be aligned with business strategy, we don’t see any reason why you can’t use Six Sigma for L&D.

We’re not saying you and your L&D team have to go and earn Six Sigma green belts—we’re not even saying you need a Six Sigma certification to really experience the benefits of this methodology. Look at the Lean Six Sigma process this way.

- It addresses both current processes and how they’re designed.

- It reactively reduces defects and proactively prevents them in future.

- Solutions become part of the design process for future projects.

- Business outcomes stay central to the process, since you’re seeking improvements in the name of said business outcomes.